And that’s a wrap on Harvest Season 2021

Harvest is a time we look forward to every year and this year our vineyard crews led by Vineyard Manager Efren Loeza delivered exceptionally clean, ripe fruit to the winemaking team to transform into our beautiful wines. Our winemaking team more than doubles for two months and we have crews working around the clock to process all the grapes from our estate and partner vineyards.

Miguel Calderon (left) and Vineyard Manager Efren Loeza (right) during harvest at Tualatin Estate Vineyard.

Starting early in the morning in late August we kicked off harvest season with the harvesting of Pinot Noir for our sparkling wines and then quickly moved into whites, rosés and then reds. We had an unseasonably warm and dry growing season that then quickly cooled down in late September. This slowed down the ripening in the final stretch to build flavors and tannins in the grapes while retaining natural acidities and moderating alcohol levels. Think of the difference of how slow cooking builds a lot of flavor over flash frying. This will result in concentrated color, richness and structure in the red wines from 2021 and aromatic, flavorful and balanced for the whites and rosés.

Greg Urmini, Director of Winemaking & Vineyards

Our Director of Winemaking & Vineyards, Greg Urmini, shared “the grapes for the Bernau Estate Méthode Champenoise Brut and Rosé, White Pinot Noir and Maison Bleue arrived first and tasted fantastic! We then received fruit for our Pambrun, Pinot Gris and our Pinot and Chardonnay wines. The team is really happy with the overall quality of the fruit. The phenolic maturity in the seeds and skins were optimal while the brix and acids were perfectly aligned for each varietal to express its typicity and capture the site of each vineyard.”

We had a full house in the cellar with bins of fruit everywhere you looked but everything fermented nicely and quickly so we were able to make room for the remainder of the fruit as it arrived, according to Urmini. The team strengthened our arms with twice daily ‘punch downs’ in each fermentation vessel to assure the proper extraction was achieved to fully develop the flavors and colors we want in our red wines.

The rains in October came at an opportune time for us to do some work in the cellar and catch our breath in the vineyards before harvest came to a successful end in mid-October. Our attention then turned to fermenting, pressing and barreling down our wines before topping and running chemistries on our 2021 wines as they initiate their malolactic fermentation, the conversion of malic acid into lactic acid within a wine to soften the acidity.

We're very happy with the incredible color and taste in this year's harvest and can't wait for you to try our new vintages. Willamette will start bottling our first 2021 wines in December and you will be able to find the 2021 Whole Cluster Rose’ of Pinot Noir beginning in February 2022 as our first release of the year.

What is an AVA and Why is it Important to Wine?

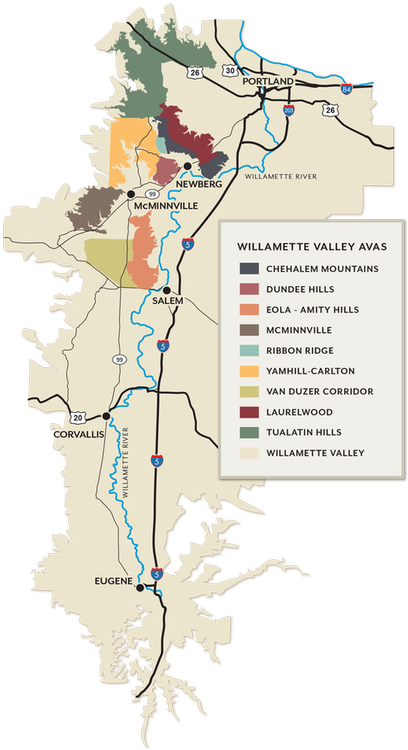

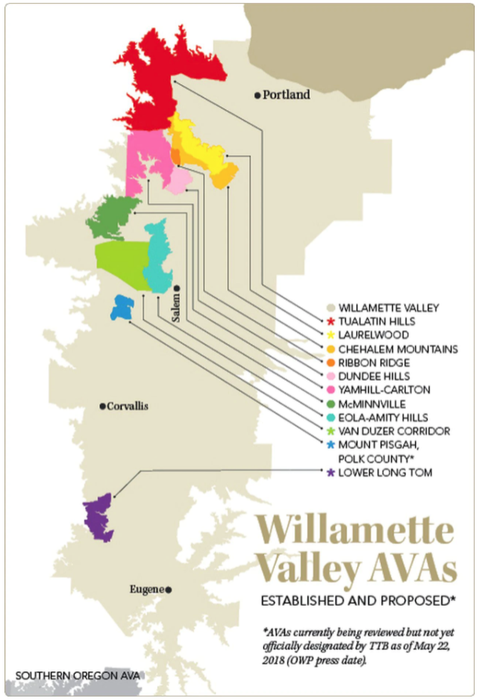

AVA stands for American Viticultural Area and is a defined wine grape-growing region. There are 257 AVAs in 34 states and 18 AVAs in Oregon. Oregon’s northerly latitude means grapes get extra sunlight to grow and crisp, cool nights to help grapes retain their acidity. Oregon’s wine pioneers thought that combination meant Oregon grapes would naturally achieve mature, balanced flavors and full varietal character according to Oregon Wine and they were right. Today the suitability of Oregon for great wine is unquestioned.

Each AVA is unique in its geographic location, climate soil and topography. When an AVA is designated on the wine bottle’s label, 85 percent of the grapes used to make the wine must be sourced from that AVA. If a wine label states Oregon, an Oregon county or an AVA wholly within Oregon, 100% of the grapes must be from Oregon and 95% from that appellation of origin.

Willamette Valley Vineyards has three Tasting Rooms and six estate vineyards in the Willamette Valley AVA.

Willamette Valley AVA

The Willamette Valley AVA is the largest AVA in Oregon and was named the Wine Region of the Year in 2016 by Wine Enthusiast Magazine. In July 2021, the Willamette Valley wine region was formally recognized by the European Union through Protected Geographical Indication Status. This milestone recognizes the quality of Willamette Valley wine and protects the Willamette Valley name from misuse and fraudulent labeling around the world. Only two regions in the US have this distinction – Napa Valley and now the Willamette Valley.

This AVA is more than 100 miles long and spans 60 miles at its widest point from the Coast Range to the West and the Cascade mountains to the East, the Columbia River to the North and just South of Eugene. The major cities within the AVA are Portland, Salem (the state Capitol), Eugene, Corvallis, McMinnville and Newberg.

Willamette Valley AVA is home to Willamette Valley Vineyards Estate Tasting Room in the Salem Hills, our McMinnville Tasting Room in quaint downtown McMinnville and our Tualatin Estate Tasting Room in Forest Grove and the region is also home to most of Oregon’s wineries – 676 wineries call this AVA home to be exact!

Climate: Known for having a mild climate with cool and wet winters, and dry and warm summers.

Soil: The Willamette Valley is an old volcanic and sedimentary seabed that has been overlaid with gravel, silt, rock and boulders brought by the Missoula Floods from Montana and Washington between 10,000 and 15,000 years ago.

Our Estate Vineyard is planted on an old west-to-southwest facing volcanic flow. The soil type is typically a clay loam, which is permeable to roots, retentive of moisture and runs five to seven feet deep. Because this soil is so old, estimated to be 10 to 14 million years old, rainwater has percolated through this now acidic soil, breaking down the basalt, allowing the roots to tap down. Wines from this vineyard exude a sense of place and display complexity, elegance and balance.

You are only a little over an hour away from the coast at any of these major cities located in the Willamette Valley AVA:

- Salem

- McMinnville

- Forest Grove

- Eugene

- Portland

Willamette Valley Sub-Appellations

The Willamette Valley has nine smaller AVAs that have distinctive climate, soil, elevation or other features that make them perfectly suited for wine production: Eola-Amity Hills, Laurelwood, McMinnville, Ribbon Ridge, Tualatin Hills, Van Duzer Corridor and Yamhill-Carlton District.

Our Elton Vineyard is in the Eola-Amity Hills sub-AVA, Tualatin Estate Vineyard and Loeza Vineyard are both in the Tualatin Hills sub-AVA, and Bernau Estate Vineyard is in the Dundee Hills sub-AVA.

Salem - Home of Our Estate Tasting Room

In addition to being the center of the Willamette Valley and Oregon Wine Country, Salem is a big city with a small-town feel. From the nearby walking trail system starting at downtown’s Riverfront Park or hiking at Silver Falls State Park aka the “crown jewel” of Oregon State Parks there are lots of family-friendly activities to partake in.

Where to Eat and Drink:

Basil & Board - Award-winning Italian pizzeria and wine cafe

Wild Pear - Airy lunch destination

Willamette Valley Vineyards - Thoughtfully prepared pairings menu by award-winning Winery Chef DJ MacIntyre featuring fresh local ingredients to enjoy with our classic Oregon wines

Where to Stay:

Willamette Valley Vineyards Winery Suite - Wake up to sweeping vineyard views from your own private suite on-site

Grand Hotel - A polished downtown hotel two blocks from Riverfront City Park and five blocks from the Oregon State Capitol

Where to Eat & Drink:

McMenamins Hotel Oregon - Offering a rooftop bar with spectacular views of downtown

Nick’s Italian Café - Homey Italian mainstay featuring pasta, wood-fired pizza & a brick-walled bar with a pool table

Willamette Valley Vineyards McMinnville Tasting Room - Enjoy a flight of your favorite Willamette wines on Third Street

Where to Stay:

Atticus Hotel - A boutique luxury lifestyle hotel in Historic Downtown

Douglas on Third - Beautiful apartment units with full kitchens and all the comforts of hotel amenities located in downtown McMinnville

McMinnville - The Heart of Oregon Wine Country

“Oregon’s Favorite Main Street” is also known as Downtown McMinnville’s tree-lined Third Street with quaint restaurants, cool coffee shops, winery tasting rooms and boutiques. You’ll also want to visit the world-class Evergreen Aviation & Space Museum where you can see the original Spruce Goose.

“Oregon’s Favorite Main Street” is also known as Downtown McMinnville’s tree-lined Third Street with quaint restaurants, cool coffee shops, winery tasting rooms and boutiques. You’ll also want to visit the world-class Evergreen Aviation & Space Museum where you can see the original Spruce Goose.

Forest Grove - Home of Our Tualatin Estate Tasting Room

Forest Grove is located west of Portland surrounded by many farms that are open to culinary enthusiasts wanting access to the freshest and finest ingredients including America’s first successful craft sake’ producer, Saké One, where you can enjoy premium Japanese and American saké in their Tasting Room.

Where to Eat & Drink:

Biscuitology - Biscuit centric southern country style cafe

Ridgewalker Brewing Company - An array of classic comfort bar fare & a focus on beer on tap in a rustic setting with modern decor.

Urban Decanter - Wine bar and wood-fired oven bistro

Zesti Food Carts - 30 spot food cart pod in a garden setting

Where to Stay:

McMenamins Grand Lodge - A former Masonic & Eastern Star property peppered with unique rooms, restaurants, a spa, free live music and events

Top Chef Fan? Check out our itinerary inspired by Season 18 of Top Chef Portland for more fun places to go around the state!

References:

Oregonwine.org

ABCs of Oregon’s AVAs, Oregon Wine Press

https://en.wikipedia.org/wiki/Willamette_Valley_AVA

https://www.willamettewines.com/about-the-valley/oregon-pinot-noir/wine-origins/

Natural Cork, Plastic or Aluminum Screw Caps – Which is Best?

Since the winery's founding in 1983, Founder Jim Bernau has made stewardship of the land a key principle in our winemaking and farming practices. As a native Oregonian, the importance of sustainable farming practices is integrally woven into Willamette Valley Vineyard’s mission. That’s why we insist on using natural cork enclosers in all our wines and why our winery was the first in the world to use cork certified through the Rainforest Alliance to Forest Stewardship Council® standards.

What makes natural cork more sustainable than a plastic or aluminum screw cap? The millions of acres of cork tree forests pull carbon from the air and pump out oxygen, helping to offset our carbon footprint. The bark from just one tree can be harvested several times over the years, meaning the tree is never cut down but continues to sequester carbon throughout its long life.

What about the wine itself – does the enclosure really matter? Simply put, yes. While there are a multitude of factors, natural cork seals in the bottle quicker than plastic or aluminum screw caps. That means natural cork provides an aging advantage and significantly reduces the chance of anerobic, off-aromas developing in the wine.

{Winemaker Joe Ibrahim visits cork forests in Portugal and helps to gently peel the bark from the tree trunk.}

Are there negative impacts of alternate enclosures? With the entrance of alternate enclosures, the cork forests and the communities that farm them are under threat of wine producers and consumers who are turning to unsustainable enclosures like plastic.

Not only are these trees losing their financial caretakers, but many species, like the now endangered Iberian Lynx, are now losing their homes.

Why don’t all wine producers use natural cork? A big factor is price. High quality natural corks are double the price of plastic or aluminum alternatives. We have long put an emphasis on choosing what is right for the environment, as well as our consumer.

In 2010, we were honored with the Rainforest Alliance’s prestigious Sustainable Standard-Setter Award. Tensie Whelan, President of the Rainforest Alliance, commended us for our long-time leadership in agriculture and forestry: "Willamette Valley Vineyards’ efforts to provide sustainable livelihoods, conserve biodiversity and minimize environmental impacts have solidified Willamette Valley Vineyards as a leader of sustainable agriculture and forestry. Willamette Valley Vineyards has long been at the forefront of environmental conservation through the pursuit of FSC-certified cork, waste management near riparian zones, and investment in alternative fuels."

Winemaker Joe Ibrahim on a visit to a cork tree farm in Portugal.

Want to learn more about natural cork? Willamette Valley Vineyards created the Cork ReHarvest natural cork recycling program. This program was responsible for placing receptacles in all Whole Foods nationwide and other select retailers to collect cork and turn them into products like shoe footbeds, insulation and more!

Patrick Spencer, the past Sustainability Coordinator for Willamette Valley Vineyards, helped turned this program into the Cork Forest Conservation Alliance (CFCA) in 2008. You can watch his Ted Talk here.

Celebrating 41 Harvests and The First Crop from Loeza Vineyard

It is hard to imagine, but Efren Loeza has been in the vineyard longer than the winery’s Founder, Jim Bernau. Efren came by this unique distinction through Willamette Valley Vineyards’ merger with Tualatin Estate Vineyard in 1997.

Efren began at Tualatin Estate Vineyard in 1979 at the age of 17 and has worked in the vineyard ever since. Even more surprising, the person who taught Efren his first lessons in vine care, Jose Ortiz, is still working at Tualatin Estate. Jose learned his skills from pioneering viticulturist, the late David Foster.

Efren came to Oregon from Michoacán, Mexico with his father Marcos, uncle Juan and three friends when he was 16 years old. He worked on a strawberry farm during the day, an onion warehouse at night and worked seasonally with blueberries and cucumbers, too. They all lived in the same cabin on the farm and at night they entertained themselves by listening to the radio and playing cards or dominoes. On Friday nights the cabins would all get together and have potlucks.

Efren has 11 brothers who all ended up coming to the United States to work and two sisters who went to California. His brother Miguel is now in his 30th year as the Foreman at Tualatin Estate Vineyards.

Originally hired by Foster to work at Tualatin Estate Vineyard, he told Efren “if you do good work, you could work here for 20-30 years.” He also told Efren “you ask too many questions, but because you do, you will run this place someday.” Efren worked with Foster for 14 years and is very proud to follow in his footsteps managing the vineyards.

When asked about his favorite memory of working at the winery Efren said it was when Founder Jim Bernau showed up at Tualatin Estate and asked him his name and if he liked working there. Jim told him he wanted to keep people who loved working there, like him. In 1997, Willamette Valley Vineyards merged with Tualatin Estate and true to his word, Jim kept Efren and the staff.

His least favorite thing to do is “dropping the fruit” from the vines. It makes him sad to have a vine with 35-40 clusters on it and cut half of the fruit that is lagging in ripeness or size. The process of thinning out the grape clusters is called green harvesting — removing the fruit that it still green when the rest of the fruit has turned color. This allows the vine to put its energy into a smaller crop of the remaining fruit is healthier, resulting in more flavor and concentration. Each vineyard and grape varietal has different amounts of fruit that has to be dropped depending on the winemaker’s preference and varietal being grown.

During harvest Efren sometimes doesn’t sleep well as he worries about the vines and the grapes. “If the weather app shows a week of sunshine, I can sleep that week. If it is a week of rain, I don’t sleep so well,” says Efren.

As Vineyard Manager for all of our vines from Tualatin Estate in Forest Grove to the Estate Vineyard in Turner, Efren has more than 500 acres under his supervision.

When asked about some of his proudest moments working at the winery he lists winning the Oregon Wine Board’s first Vineyard Excellence Award in 2016 and being recognized as Employee of the Year by his fellow employees. He’s also proud of designing many of our vineyards including the row design, trellis and vine layout — something a lot of vineyards have to hire outside consultants to do. He is very devoted to the land — Efren’s careful vineyard practices and stewardship of the land have earned LIVE and Salmon-Safe certifications for all of our estate vineyards.

In honor of Efren’s contributions to the winery and the Oregon wine industry, we planted Loeza Vineyard in his family’s name in 2015. The 39-acre vineyard is located in Gaston and is planted with Pinot Gris and Pinot Noir. In 2020, we harvested the first crop from Loeza Vineyard for our estate wines.

Perfect Pairings: Chocolate Hazelnut Torte with Whole Cluster Pinot Noir

Winery Chef DJ walks us through this delicious simple recipe that is the ultimate crowd-pleasing dessert course. It pairs beautifully with the fruit forward, versatile notes of our Whole Cluster Pinot Noir.

Make sure to post and tag us in your decadent creations!

@WillametteValleyVineyards

Whole Cluster Pinot Noir

Years ago, Founder Jim Bernau began experimenting with Pinot Noir by gently dropping hand-picked whole clusters in a chilled stainless fermenter, pushing all the oxygen out with CO2 and sealing the vessel tight. What happened next was magical — the berries started to swell and turn pink. When they burst, they released the most aromatic, fermenting Pinot Noir.

Purchase Whole Cluster Pinot Noir

Get to Know the Women Behind Willamette Valley Vineyards

Willamette Valley Vineyards is honored to have 56% of our staff and 63% of our leadership team made up of passionate women dedicated to shaping the Oregon wine industry.

Below are just a few of the incredible women on our team, shaping everything from Wine Club to daily operations in the Tasting Room.

Tayler Herman

Wine Club and Ownership Manager

How long have you been with Willamette? 4 years.

What was your first experience with wine and what made you get into the industry? I grew up in Washington’s Columbia Valley, so wine was always on the dinner table and I was allowed to have small tastes from time to time. Eventually, I became the designated driver for wine tastings for my family until I could finally enjoy the tastings myself. I wanted to get into the wine industry because I have always gravitated towards the food and beverage industry and I love something that brings everyone together so naturally wine became a perfect fit for me.

What is your favorite thing about working for Willamette Valley Vineyards? I am challenged everyday when I come into work. There is never a boring day. I also love having Christine as a mentor and feel so lucky to have someone that believes in my growth and development at the company.

What is a memorable piece of advice you were given while working in the wine industry? It's easy to get caught up in providing the best possible experience to our customer and the business side of things, and it's just as important to remember that wine is something meant to be fun and enjoyable.

Julia Rentz

Hospitality Coordinator

How long have you been with Willamette? 3+ years.

What was your first experience with wine and what made you get into the industry? I was a novice wine drinker before I started at Willamette Valley Vineyards, and now my knowledge and love for this industry has aged like fine wine! (pun intended).

What is your favorite thing about working for Willamette? I get to create memorable experiences to help people celebrate the best days of their lives; I can't think of a better way to spend my days.

What is a memorable piece of advice you were given while working in the wine industry? Don't get too hung up on the details, we are in the business of making people happy!

Lauren Druse

Tasting Room Manager (McMinnville, Tualatin Estate, Maison Bleue)

How long have you been with Willamette? Five years in April!

What was your first experience with wine and what made you get into the industry? I'm Italian, so I think it was peach wine when I visited my extended family in Caporciano, Italy when I was nine. Besides that, most of my experience with wine in my twenties was serving it to customers in bars and restaurants. I ended up moving to Dundee in the heart of Oregon’s wine country in 2016, and was ready for a change after managing restaurants for more than ten years. At the time, my best friend was the Sous Chef at Willamette Valley Vineyards and he convinced me I should make the change and apply. I figured tasting rooms would allow me to continue to connect with regulars, and do all the things I really love doing in the hospitality and service industry. Plus, there is wine! He was right!

What is your favorite thing about working for Willamette? Connecting with customers, meeting new people daily, building relationships with colleagues and customers and being a small part of so many amazing life memories!

What is a memorable piece of advice you were given while working in the wine industry? Don't be afraid to think out of the box or to try new things. It doesn't matter that you don't have as much experience as some people do. Wine can be taught, and we are all constantly learning as we go. We all come to the business with different experiences and strengths. Play to your strengths.

Rylee Cutchin

Estate Tasting Room Manager

How long have you been with Willamette? About one year.

What was your first experience with wine and what made you get into the industry? My first experience with wine was from my two older sisters. They would always go wine tasting on the weekends and I grew so envious of not being able to join them. Finally when I turned 21, all I wanted to do for my 21st birthday was to go wine tasting. I actually went to Willamette Valley Vineyards to celebrate. I quickly fell in love with an environment that is surrounded by wine. Little did I know, I would eventually become the Tasting Room Manager.

What is your favorite thing about working for Willamette/in the wine industry? I love being a part of a team that works hard to continue to grow and develop new ideas, experience and offerings. It's exciting to work on innovative ideas and see them come to life. Willamette is focused on finding ways to continue to be one of the greatest tasting rooms in the valley and it's exhilarating to be a part of.

What is a memorable piece of advice you were given while working in the wine industry? "Find a way to a YES." This statement has been said to me numerous times throughout this year and this has really shaped my way of thinking in situations. Willamette always looks to find a “yes” in every circumstance and I think this has really helped the company be successful, especially this last year with all the unknowns and regulations, Willamette continues to make every guideline work.

Crystal Ashley

Winery Ambassador Manager

How long have you been with Willamette? I started May of 2015 — about to finish my 6th year.

What was your first experience with wine and what made you get into the industry? I have always loved wine and can't remember my actual first experience with it. It has been a part of so many memories in my life. My palate and knowledge are very much like wine, it gets better with age.

What is your favorite thing about working for Willamette? My favorite thing is getting to share our beautiful wine and rich history and watch others make lifelong memories. I get to learn something new almost every day and work with really great people. Everyday is rewarding and challenging.

What is a memorable piece of advice you were given while working in the wine industry? I have received so much amazing advice and knowledge during my career with Willamette. One thing that has always stuck with me is "don't just listen to others; listen to understand because feedback is a powerful tool."

Self Enhancement, Inc. Donation

Willamette Valley Vineyards donated $1 from each bottle sold in June to Self Enhancement, Inc (SEI). This local non-profit provides invaluable support, guidance and opportunities for underserved youth to achieve personal and academic success.

Our wine enthusiast customers were eager to support the cause and as a result, WVV was able to donate more than $24,000 to SEI!

SEI is one of the region's leading multi-service organizations, providing thousands of youth, families and adults with a wide variety of education and social services on an annual basis.

To learn more about Self Enhancement Inc., click the button below!

Patio Pairing with Vintage 44 Pinot Noir

Winery Chef DJ MacIntyre shares one of his favorite vegetarian recipes to pair with our Vintage 44 Pinot Noir. We hope you enjoy this cooking tutorial video for a portobello mushroom and fried pepper burger.

YIELD:

4 burgers

INGREDIENTS:

- Portobello Mushroom, whole with stem removed - 4 each, medium sized

- Italian Parsley (leaves and stems) rough chopped - 2 bunches

- Green Onion, cleaned, roots removed & rough chopped - 1 bunch

- Shallot, chopped ½” - 1 each

- Oregano, dried - 1 Tbsp

- Thyme, dried - 1 Tbsp

- Red Wine Vinegar - 1 cup

- Whole Grain Mustard - ¼ cup

- Kosher Salt - 2 tsp

- Black Pepper, ground - 1 tsp

- Extra Virgin Olive Oil - 2 cups

- Chevre, goat cheese - 1 cup

- Anaheim Pepper, large 6-7” long - 2 each (if small use 4 each)

- Onion Rings, baked or fried - 4 each

- Micro Greens or Arugula - 2 cups

- Potato Burger Bun - 4 each

METHOD:

Using a Vita-Mix or a high speed blender, add the chopped parsley, scallion, shallot, dried herbs, vinegar, mustard, salt and pepper. Start the blender on slow and gently pour the oil into the blender to make an emulsion. You will need to raise the speed of the blender to high as you start to add the oil. The vinaigrette is done when you have an evenly colored green emulsion that is thick and viscous. Remove vinaigrette from the blender and hold on the side.

Heat your BBQ grill up to 450° and cook your onion rings to desired temperature. Next, place the peppers on the grill and let cook for 8-10 minutes to achieve nice charring on all sides. Remove peppers from the grill and place in a bowl or Tupperware, then seal with a lid or plastic wrap and let sit.

Prepare your mushrooms first by basting all sides of the mushrooms with the vinaigrette and sprinkling a little salt and pepper to taste. Next, grill your mushrooms, about 5 minutes per side, basting them ever so often. While the mushrooms are grilling, remove the peppers from the bowl. The waxy skin should peel off very easily from inner meat. Then deseed the Anaheim pepper and cut to the size of the burger bun, roughly in half. Place the chevre in a separate bowl and slowly whisk in the remaining vinaigrette. You will not use all the vinaigrette, just enough to loosen the chevre to a creamy/spreadable consistency. Baste the mushrooms once more, then remove from the grill. After toasting the burger buns, spread the chevre mixture on each side, then add the grilled mushroom, pepper half and onion ring. Finish by placing the micro greens or arugula on the onion ring and the top half of the bun.

Serve and enjoy!

Patio Pairing with Estate Rosé of Pinot Noir

Winery Chef DJ MacIntyre shares one of his favorite patio pairing recipes. We hope you enjoy this cooking tutorial video for artisan flatbread.

Flatbread with Beer Cheese Sauce

Pairs with 2019 Estate Rosé of Pinot Noir

Beer Cheese Sauce

YIELD: 1.5 QUARTS

INGREDIENTS:

Garlic,minced fine - 2 tsp

Vegetable stock - 2 cups

Heavy cream - 2 cups

Your favorite beer - 1 can

Cheese (cheddar, brie, gouda, etc.) chopped into ½” chunks - 2 cups

Corn starch - ¾ cup

Bay leaves - 2 each

Black pepper, ground - 2 tsp

Kosher salt - 1 tsp

METHOD:

In a heavy duty stock pot over medium-high heat, add the garlic, vegetable stock and cream, then bring to a boil. Once a boil has been achieved, turn the heat to low. Add the spices and beer, then bring to a simmer. In a mixing bowl add the cubed cheese and cornstarch. When the beer broth is heated thoroughly again, add the cheese and cornstarch. Using a whisk, stir until the cheese starts to melt. Then use a hand immersion blender to break down the remaining ingredients into a thick creamy sauce. Strain cheese sauce through a strainer and refrigerate for 1 hour. Sauce should be very dense. Store refrigerated until needed.

Flatbread Dough

YIELD: 14 EACH x 9 INCH

INGREDIENTS:

Fast Rising Yeast - ¼ tsp

Warm Water #1 - 2 Tbsp

Pizza Flour, “00” Mimosa - 1,375 grams

Warm Water #2 - 875 grams

Kosher Salt - 22.5 grams

Canola Oil - 2 ¼ tsp

METHOD:

Mix yeast with warm water #1 in a small bowl and let bloom for 5 minutes. Then add the flour, water #2 and salt to the mixing bowl, then mix with the dough hook attachment. While mixing, add the canola oil. Mix the dough until it is not sticking to the sides and is wrapping itself around the dough hook — add more flour if needed. Dough should only stick to itself.

Leaving the dough in the bowl, cover tightly with plastic wrap, then add another layer of plastic wrap over the bowl. Leave the dough out overnight at room temperature.

Portion dough into 9 oz. balls (approximately 1 ⅛ cups) and place into a greased white proofing tray or covered Tupperware. Refrigerate any leftovers. Proof dough balls at room temperature for 1 hour. Any longer and the dough will be over proofed and loose. Alternately, if it is summer and the weather is hot, try proofing for only 30 minutes.

Dust hands and tops of dough balls with flour before stretching and tossing. Dough should stretch but not be loose and “runny.” Stretch dough to about 10 inches in diameter.

At this point you are able to add the beer cheese sauce and your favorite toppings. Then bake or grill at 400-450° for 8-10 minutes or until crisp.

For the remaining dough, you can cook both sides of the flatbread skin on the flattop or griddle set at 200°. Then let cool to room temperature for about 20 minutes. Transfer them to a large air-tight container and refrigerate/freeze until needed.

Patio Pairing with 2017 Père Ami

Food and wine can provide comfort during challenging times, so Winery Chef DJ MacIntyre is sharing one of his favorite patio recipes. We hope you enjoy this cooking tutorial video for wild mushroom and herb crusted steelhead to pair with our 2017 Père Ami.

Wild Mushroom and Herb Crusted Steelhead

Pairs with 2017 Père Ami

4 servings

INGREDIENTS:

Steelhead, filet, cleaned - 1 side

Olive oil - 4 Tbsp

Lemon juice - 2 Tbsp

Dried porcini mushroom, ground medium fine - 4 Tbsp

Dried shiitake mushroom, ground medium fine - 3 Tbsp

Dried black trumpet mushroom, ground medium fine - 2 Tbsp

Lemon zest, dried - 1 tsp

Granulated garlic - ½ tsp

Thyme, dried - 1 tsp

Rosemary, dried & ground - ½ tsp

Oregano, ground - 1 tsp

Kosher salt - 1½ Tbsp

Black pepper, ground fine - 2 tsp

METHOD:

Mix all the dry spices together with the mushroom powders in a bowl. Next, squeeze the lemon juice over the whole filet. Then cover the filet with the olive oil and season the entire fillet with the ground mushroom rub. Let the fish sit for 10 minutes, allowing the mushrooms to bloom. Place steelhead on a cedar plank and grill at 350° for 8-10 minutes or until desired internal temperature is reached (145° recommended). Serve with earthy vegetables and rice and enjoy!